| Appearance | White / Grey Granulose Powder |

| Dry Density | 789(±)10%(kg/m3) 49,26,8(±)10%(lb/ft3) |

| Thermal Conductivity | 0,121 W/mK 0,070 Btu/h.ft.°F |

| Sound Insulation | 22,4dB |

| Compressive Strength | CSII 2,84 (N/mm2) CS II 411,44 (lbf/in2) |

| Water Absorption | 0,46 (kg/m2) W0 0,654 (lb/in2) W0 |

| Water Vapor Permeabilty | 9,4µ |

| Surface Hardness | 43 Shore D Hardness (average) |

| Fire Strength | A Class |

| Shelf Life | 12 Months |

| Application Method | Machine, Steel Trowel |

| Coverage Area | 1.3 cm (1/2 inch) Applied Thick. Covers 3.7 m - 4.0m2 (40 - 43 sqft) aprox. |

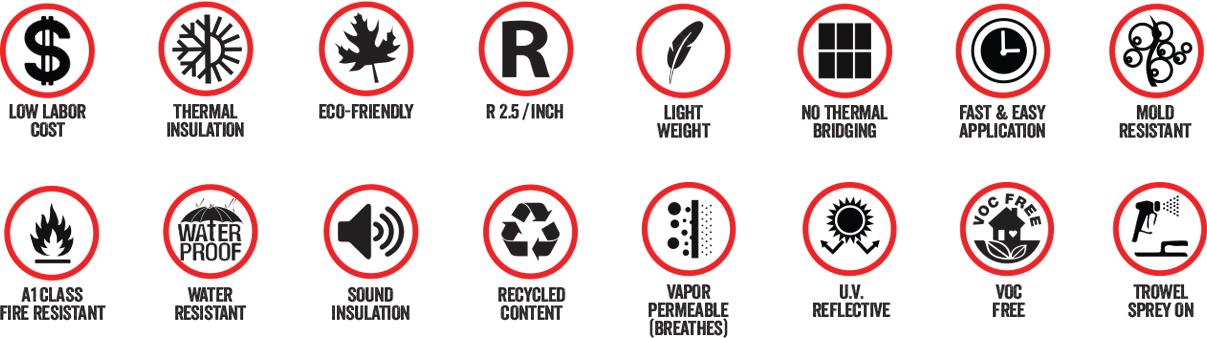

Applied on exterior facades, our multipurpose single component insulation coating is a Sustainable, A1 / Class 1 Fire, Water, Sound, and Thermal Resistant material with a High Diffusion characteristics (Breathability), available in white or grey color. LAVACOAT Insulated Exterior Coating insulates and protects buildings from heat, sound, water & fire using a proprietary blend of inorganic natural aggregates.

USAGE AREAS

LAVACOAT Insulated Exterior Coating is applied directly on exterior facades of buildings, (concrete, masonry, brick, aerated concrete, pumice brick). It can be applied in the same manner as stucco and many types of decorative finishes can be achieved. LAVACOAT Insulated Exterior Coating can be used in new construction and renovation of existing buildings for the purpose of improving the water resistance and insulation values. *NOTE: Cannot be applied directly onto Metal, Wood & Drywall, without using LAVACOAT Metal / Wood / Concrete / Drywall Primer.

PREPARATION

PREPARATION Pour each bag of LAVACOAT Insulated Exterior Coating into a clean vessel or commercial grade concrete/stucco/plaster mixer. (Water requirements may vary depending upon the type of mixing equipment used). Mixing using a HAND-HELD mixer; Use between MIN 12.5 - MAX 13.5 Liters (MIN 3.3 - MAX 3.5 Gallons) of water, and mix for 6-7 minutes at low or medium speed

Mixing using a COMMERCIAL GRADE CONCRETE, STUCCO, PLASTER mixer; Use between MIN 13.5 - MAX 14 Liters (MIN 3.5 - MAX 3.7 Gallons) of water, and mix for 6-7 minutes at regular mixer speed.

It is recommended that the mixture should be left to stand for 2 - 3 minutes after mixing.

The final consistency, after proper mixing, will result in the fully mixed product FALLING or DROPPING OFF THE TROWEL- SLOWLY.

PLEASE WATCH VIDEOS ON www.lavacoat.com TO ENSURE CORRECT MIXING CONSISTENCY.

APPLICATION

The surface of application area must be free from dust, dirt, oils, surface contaminants, etc. NOTE: The application is applied in the same method as a stucco. For a single coat application, it is recommended to use minimum 1.5 cm [5/8 inch) thickness. For TWO coat applications, after applying the scratch/rough coat and left to dry for 6-12 hrs, apply a thin layer max. 5 mm (3/16 inch] top coat. All types of decorative surfaces can be achieved with appropriate tools (float, trowel, sponge, etc) for the top coat. Leave to dry for 24-48 hrs. PLEASE WATCH VIDEOS ON www.lavacoat.com TO FIND OUT MORE.

USAGE AREAS

LAVACOAT Insulated Exterior Coating is applied directly on exterior facades of buildings, (concrete, masonry, brick, aerated concrete, pumice brick). It can be applied in the same manner as stucco and many types of decorative finishes can be achieved. LAVACOAT Insulated Exterior Coating can be used in new construction and renovation of existing buildings for the purpose of improving the water resistance and insulation values. *NOTE: Cannot be applied directly onto Metal, Wood & Drywall, without using LAVACOAT Metal / Wood / Concrete / Drywall Primer.

PREPARATION

PREPARATION Pour each bag of LAVACOAT Insulated Exterior Coating into a clean vessel or commercial grade concrete/stucco/plaster mixer. (Water requirements may vary depending upon the type of mixing equipment used).

APPLICATION

The surface of application area must be free from dust, dirt, oils, surface contaminants, etc. NOTE: The application is applied in the same method as a stucco. For a single coat application, it is recommended to use minimum 1.5 cm [5/8 inch) thickness. For TWO coat applications, after applying the scratch/rough coat and left to dry for 6-12 hrs, apply a thin layer max. 5 mm (3/16 inch] top coat. All types of decorative surfaces can be achieved with appropriate tools (float, trowel, sponge, etc) for the top coat. Leave to dry for 24-48 hrs. PLEASE WATCH VIDEOS ON www.lavacoat.com TO FIND OUT MORE.

IMPORTANT

• The content of a bag of LAVACOAT Insulated Exterior Coating MUST be used completely once the bag is opened.

• The product must be mixed with a handheld or concrete mixer (for minimum 6 minutes) at LOW revolution.

• If the mixture prepared (MAX. 1 hour) sits too long in the vessel and loses its consistency, you must NOT add water. Consistency can be renewed only by mixing with a low revolution mixer.

• To apply LAVACOAT Insulated Exterior Coating over painted surfaces, mineral plaster and other coatings, purge the surface approximately at a rate of 70% by using paint remover chemicals, surface abrasion or other similar methods.

• Can be painted after 48 hours using ONLY water based and/or Acrylic paints.

• During the mixing process, the person mixing the LAVACOAT product must wear a pair of safety glasses or goggles and a mask for health and safety purposes. See MSDS for additional precautions.

• The product must be mixed with a handheld or concrete mixer (for minimum 6 minutes) at LOW revolution.

• If the mixture prepared (MAX. 1 hour) sits too long in the vessel and loses its consistency, you must NOT add water. Consistency can be renewed only by mixing with a low revolution mixer.

• To apply LAVACOAT Insulated Exterior Coating over painted surfaces, mineral plaster and other coatings, purge the surface approximately at a rate of 70% by using paint remover chemicals, surface abrasion or other similar methods.

• Can be painted after 48 hours using ONLY water based and/or Acrylic paints.

• During the mixing process, the person mixing the LAVACOAT product must wear a pair of safety glasses or goggles and a mask for health and safety purposes. See MSDS for additional precautions.